ENGINEERING SYSTEMS (Nottm) Ltd.

|

Engineering Systems Design & Manufacturing Facilities

|

|

|

Our workshop is equipped with a selection of CNC, semi-CNC and

conventional machine tools.

Haas, Hardinge, Harrison, Colchester, XYZ, Jones & Shipman etc.

This selection gives us the versatility to produce a range of engineered products - from one off

prototypes to medium sized batches of precision components. |

|

|

We can produce quantities of the usual selection of

miscellaneous parts, shown right, in 1's, 10's, 100's or 1000's. |

|

Hardinge Talent 8/52 with C axis and Driven tooling

|

|

|

|

We can design and manufacture special parts

using our Solid Edge 3D package.

|

When the part has been designed, we use our OneCNC CAM package to generate

the machining data which is sent to our machine tools.

|

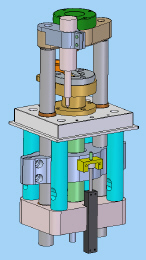

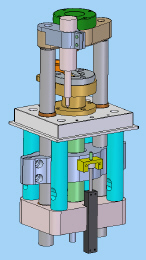

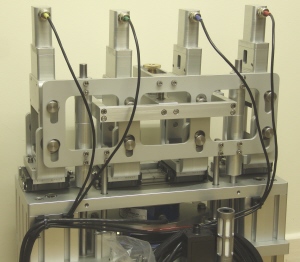

C53 Load Frame

|

Haas VF-2SS with 4th Axis

|

|

|

After machining the parts are usually de-burred and finished in our

vibratory surface finishing machine.

Further surface finishing - Anodising, Powder Coating or

various forms of Electro-plating can be arranged.

|

|

Harrison Alpha 400

XYZ vertical turret mill with 3 axis CNC control

|

C53 Load Frame

|

|

|

|

|

|

We design and manufacture mechanisms such as the loading frame,

shown on the left as a Solid Edge model, and produce the actual manufactured and assembled part,

shown on the right.

This assembly is used in one of our own testing machines. |

|

|

|

|

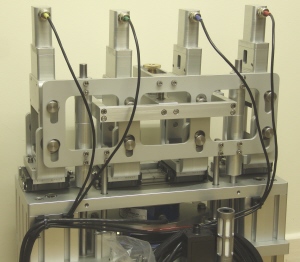

The picture on the right shows the loading frame assembled and

positioned onto the baseplate together with the electronic circuit boards. The electronic circuitry is

custom designed and manufactured by us. |

|

|

|

|

|

|

We are experienced in designing larger engineered products.

In conjunction with other manufacturers we can produce larger prototypes and low volume products

to customer specification.

The picture on the left shows a Solid Edge view of a partly

finished fabricated frame (approx. size 1000 x 1100 x 1300 mm) which will have a powder coated finish and various smaller machined parts

attached. |

|

|

An experimental test rig. The mechanical parts were designed

and manufactured by Engineering Systems. |

|

|

|

|

|

|

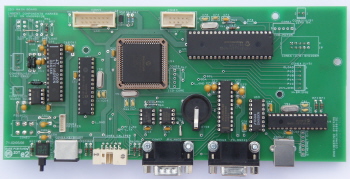

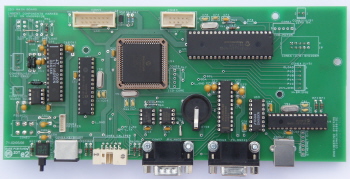

We have expertise in the design and production of electronic

circuitry and we design and manufacture all of the electronics used in our testing machines. We

can undertake the design and production of apparatus that needs to incorporate relatively straightforward

control and measurement circuitry.

The photograph on the left shows the main circuit

board used in our new C53 testing machine. The circuitry is based on the PIC microcontroller, and

controls the load measurement, motor movement, output of data and all the other control

functions necessary to operate the C53. |

|

Electronic workshop facilities include:-

- Tektronix 100 MHz digital storage oscilloscope

- Thurlby & Fluke digital multimeters

- Thurlby and various other power supplies

- Logic Analyser

- Microchip MPLAB ICD2 debugger & REAL ICE emulator for PIC microcontroller

development

- Anti-static work areas with soldering and desoldering equipment

- Seaward EMC testing equipment

Design facilities, software & computer equipment include:-

- Solid Edge, OneCNC and CAD4U CAD software for 2D and 3D

mechanical design and drawing

- Easy-PC and Hiwire schematic capture and PCB design software

- Microchip MPLAB IDE PIC development software

- Microchip C18 & C30 compilers

- Hi-tech C Z180 cross compiler

- PCs with 24" monitors etc. suitable for CAD, CAM, DTP etc.

- A5 to A3+ inkjet & laser printing facilities

Testing equipment:-

500kg. Traceable deadweight loading facility

FOR FURTHER DETAILS OF OUR DESIGN AND MANUFACTURING FACILITIES,

PLEASE CONTACT

SIMON HAYDOCK OR DENIS COOPER

TOP OF PAGE

TOP OF PAGE